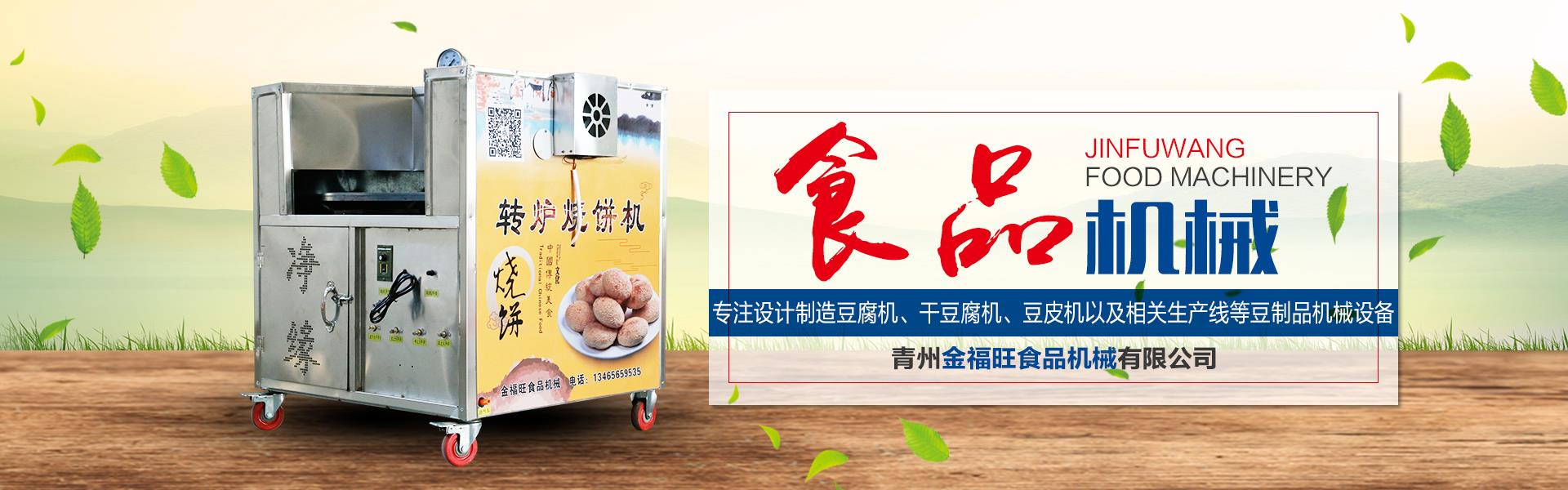

Introduction to the structure and working principle of the automatic biscuit maker

Confirmation of the intermittent mechanism of the automatic biscuit maker

The process of making pancakes is divided into the process of brushing, heating, and discharging. It is very important that the process of brushing the surface and the movement of the stove are coordinated. Therefore, the intermittent mechanism is mainly used here. Common intermittent mechanisms include incomplete gear mechanism, ratchet mechanism, and sheave mechanism. Although the incomplete gear mechanism is easy to manufacture, simple in structure, and reliable in operation, it has a large impact during work and can only work in a light-load environment.

The ratchet mechanism is simple to manufacture, reliable in operation, and simple in structure, but it has large impact and noise during operation, and has poor motion accuracy. The sheave mechanism is simple in structure, small in size, high in mechanical efficiency, and can be indexed more smoothly and intermittently. There is only flexible impact during work, and it can work at medium speed. After comparison, the groove wheel mechanism is selected as the index intermittent mechanism.

working principle

The motor transmits the power to the drive shaft through the gear transmission, and then the power transmission dial 1, dial {{{{2}}}}, cam and gripper through the bevel gear transmission and chain transmission Institutionally. In each cycle, on the one hand, the dial 1 dials the groove wheel 1 through 7 {{{{2}}}}, which is the groove wheel 1 Drive the furnace through 7 {{{{{{{}}}}}}}, just below the hole on the face plate, then the face plate is lowered by the action of the cam until the hole on the face plate is covered in the furnace The upper stop stops descending, at this time, the dial {{{{2}}}} dials the groove wheel {{{{2}}}} to turn 7 {{{{{{7} }}}}}, That is, the groove wheel {{{{2}}}} drives the face brush through 7 {{{{2}}}}, brush the face on the stove, brush the face After the end, the cam will drive the face plate to a higher position and stop to wait for the next cycle; on the other hand, when the automatic biscuit maker rotates, it will move relative to the fixed shovel to separate the cooked cake from the stove. The slice mechanism will grab the cooked cakes on the conveyor belt, and then the conveyor belt will transfer the cakes out.